Background

This Indiana-based, vertically integrated company provides the full gamut of products and services—from crude oil to finished products (fuel, lubricants, etc.) and commercial fuel services, including delivery to local customers. The initial engagement was for our team of reliability experts to conduct an enterprise-wide Reliability Assessment to determine the current state, measure the reliability maturity level using our proprietary Reliability Systems Review (RSR), and make recommendations for future improvement. CountryMark Refining was found to be at Level 3, or Enlightened; which makes it a great candidate for supplemental project work to relieve the organization of time and resources but yet meet goals of improving their asset strategy program.

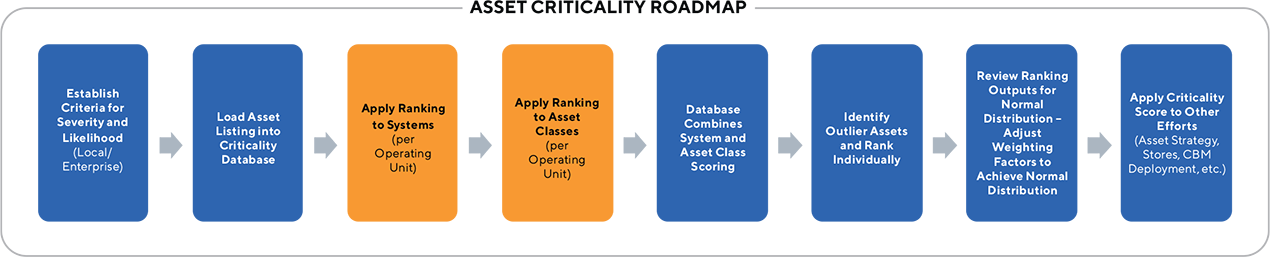

The assessment showed that there were still opportunities across the organization to enhance performance and production by fine-tuning maintenance strategies some of which could be done independently by the client. Allied supported the initiatives by providing onsite training, raised awareness of reliability by teaching fundamental courses, and instilling a more proactive culture; ultimately paving the way to implement condition-based maintenance (CBM) best practices across the enterprise. Separately from the refinery, Allied Reliability aided the CountryMark Energy Resources division at the wellsite by assisting and building an asset hierarchy template and populating a sample pool for them to identify the assets needed.