Oil Mist Lubrication Systems

Four-Cell Cooling Tower

Northeast Oil Refinery

Philadelphia, PA

Industry | Oil & Gas

- One Year Payback

- Two Gearbox Failures Eliminated per Year

- Zero Oil Spill Risk

Business Challenge

This oil refinery was experiencing failures on a minimum of two gearboxes each year. The losses were catastrophic, with the output shaft bearings dropping into the gearing, resulting in a $50,000 repair on each gearbox. Excessive water contamination in the gearboxes caused corrosion, rust, and sludge formation in the gearbox reservoirs.

T.F. Hudgins Solution

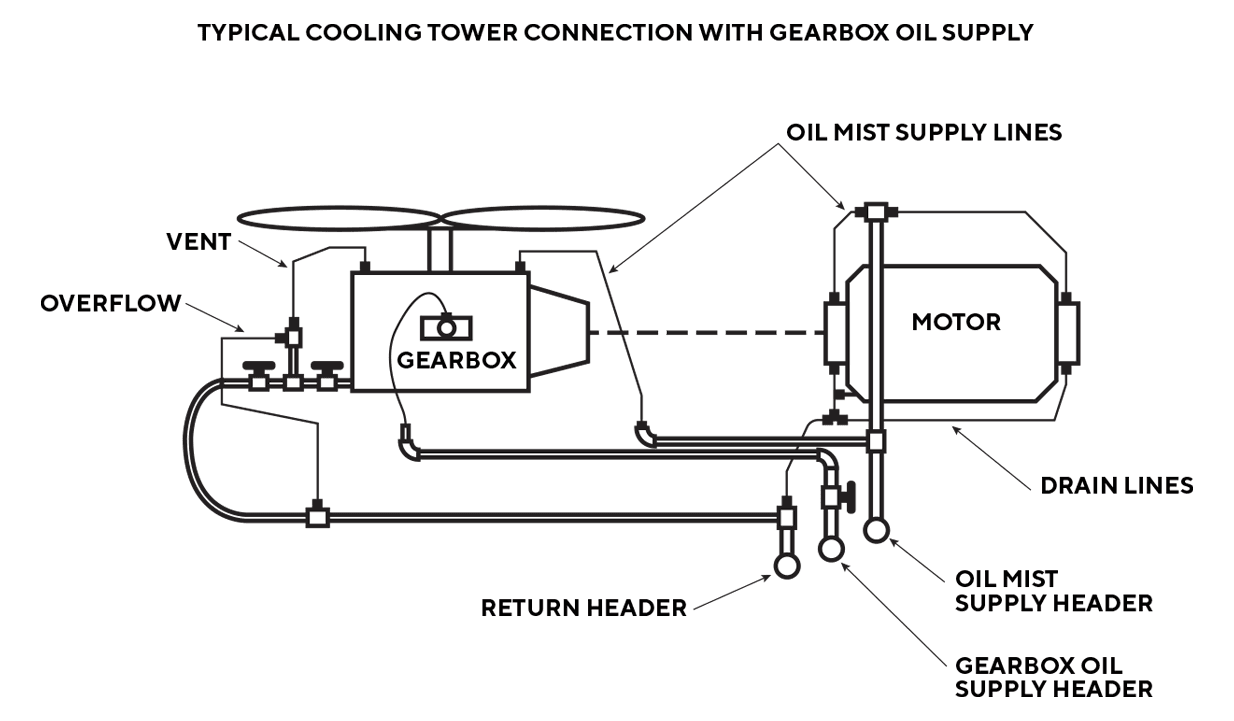

The client decided on an oil mist lubrication system with a bulk oil fill and drain system for each gearbox. The gearbox was converted by removing the oil pumps that would force the contaminated gear oil up to the bearing. The output shaft bearing was converted to pure oil mist lubrication, with the gearbox now purged with oil mist. The gearbox was supplied with synthetic lubricant, as was the oil mist system. (See figure 1)

Business Impact

After one year of operation, there were no failures, and this success continued for many years. The payback on this complete system was less than one year.

Key improvements documented for this success:

- Elimination of a minimum of two gearbox failures each year.

- Safety improvement, no entry permit for two mechanics, and locking out of motor and scaffolding inside the cooling tower cells.

- Environmental improvement; no oil spill risk with draining and filling gearbox.

- Crane for removal of gearbox and installation of the repaired gearbox, with required watch personnel on the ground.

- Winter windmilling in reverse was an issue. Oil mist now coats all internals with clean, fresh oil.