What is that Chirping Belt Telling You?

Have you ever entered a work order for a chirping belt only to have it sit there for weeks or sometimes even months because no one feels there is a major issue, so they mark it as a low priority? This can be common especially on multiple belt drives when mismatched belts are an issue. It can also become worse since many organizations never go back and adjust tension as needed on new belts after their run-in period.

Many people think that chirping is not a significant issue, it's more annoying than anything else. They understand it is not best practice, but it is the world we live in. Most of the time it's true but as the issues get worse the failure modes will change. In my experience, each chirping belt should be looked at case by case to really understand what is going on and plan accordingly.

The following is an example of where a chirping belt was a more significant issue than just a little noise. The fan was making a little noise and using a strobe you could see some slapping. In the end, I had seen and heard worse, and it was one that had been written up for almost two months when I took the infrared (IR) image.

This setup is unique as it was a fan driven by two 250-hp motors. There are multiple belts on each motor and in the application, with the slipping belts it was set up, so the motor belts were on every other groove of the motor sheave and the fan had a belt in every groove. This way the load is spread evenly over the shaft of the motor. The motors have a 10-groove sheave as does the fan.

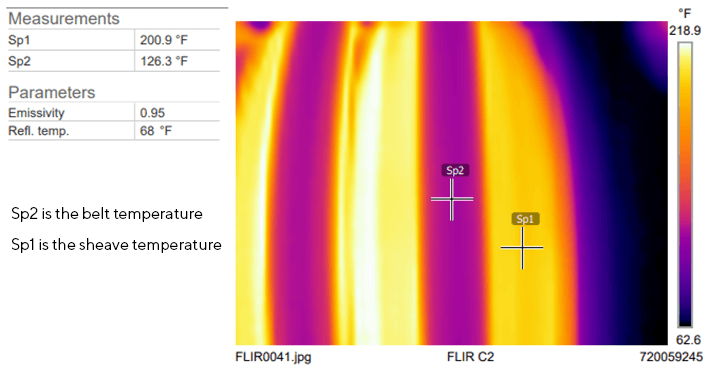

The following IR image was taken off a fan with a chirping belt. You can see the slipping belt is generating extreme heat levels.

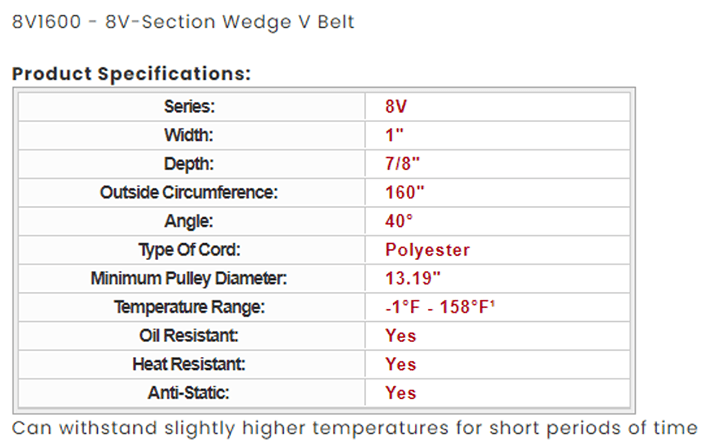

Below is the belts spec sheet:

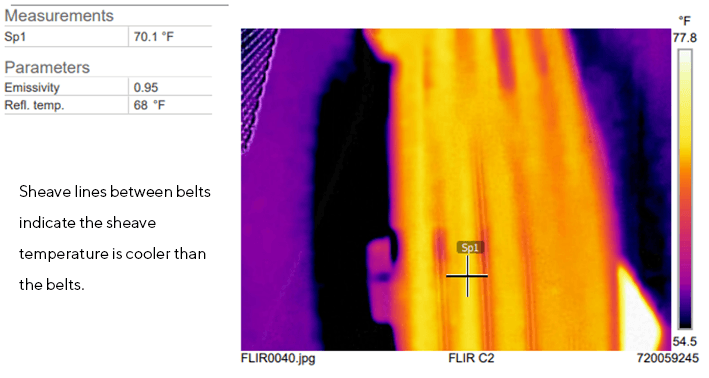

The following is an image of the same fan design with the belts properly tensioned. The setup is slightly different too because the motor sheave is just a 5-groove sheave. One motor has the sheave set further out on the motor shaft to line up with 5 grooves on the outboard side of the fan sheave. The other motor has the sheave set closer to the bearing to line up with the inboard grooves of the fan sheave. If you look at the overall temperatures of the belts, they are running much cooler. If you look closely at the image you can see the sheave is also running cooler, than the temperature of the belts.

This is meant to just show that even though the belts are not making a lot of noise or slapping badly there are issues lurking that can become catastrophic quickly as the failure mode moves down the P-F Curve. The belts are designed to run at a max temperature of 158°F and although the belts are not at that temperature the sheave they are running on is well above that temperature at 200°F. Since the sheave is running at 200°F that heat is being transferred into the motor shaft and bearings.

About the Author

Mark Kingkade

In his current role with Allied Reliability, Mark is a regional analyst responsible for working closely with clients to provide valuable insights into their maintenance and reliability practices.

Mark has over 30 years of experience working in the maintenance and reliability field holding his CMRP certification since 2008. He has presented on Vibration Analysis several times at notable conferences including those organized by Noria and reliabilityweb.com. He has extensive experience having held various roles on predictive maintenance (PDM) teams, as well as expertise as a millwright planner, and a proven track record in industrial machine repair and installation.

Mark is knowledgeable in condition monitoring technologies and program development, with his core competency in vibration analysis as an ISO Cat 3 analyst but has also been involved with other technologies that include oil analysis, thermography, ultrasonic testing, motor current analysis, and motion amplification.

Mark also has experience in performing and developing procedures for acceptance testing and current state equipment inspections as well as developing operator care and basic care inspection procedures and involvement with PM Optimization work. One of his greatest passions is being allowed to mentor others that have an interest in vibration or any of the other PDM technologies.

Connect with Mark on LinkedIn.

ABOUT ALLIED RELIABILITY

Allied Reliability provides asset management consulting and predictive maintenance solutions across the lifecycle of your production assets to deliver required throughput at lowest operating cost while managing asset risk. We do this by partnering with our clients, applying our proven asset management methodology, and leveraging decades of practitioner experience across more verticals than any other provider. Our asset management solutions include Consulting & Training, Condition-based Maintenance, Industrial Staffing, Electrical Services, and Machine Reliability.

Subscribe to our Blog

Receive the latest insights on reliability, maintenance, and asset management best practices.