Gain Better Vibration Data on Critical Inaccessible Machine Components

Remote Sensor Setup Helps Maintain Centrifuge Separator

Background

It is particularly difficult to monitor the condition of critical machinery components when they are mounted in a hard-to-access location. This case study discusses the setup of a remote sensor that was installed inside a Westfalia separator to obtain better information on the condition of the spindle bearings.

Problem

This particular separator design did not provide a clear, solid path between the bearing housing and the area for a maintenance technician to access the outside of the housing for vibration data collection. The spindle assembly was mounted on isolators and vibration absorbers to allow for some flexing, which helps reduce the vibration on the housing, resulting in imbalance as it develops.

Details

The photo below shows the original centrifuge setup with the factory-installed vibration sensor, as it is typically mounted on the housing.

The next two images show the spindle assembly (left) and mounting area (right) inside the unit.

Solution

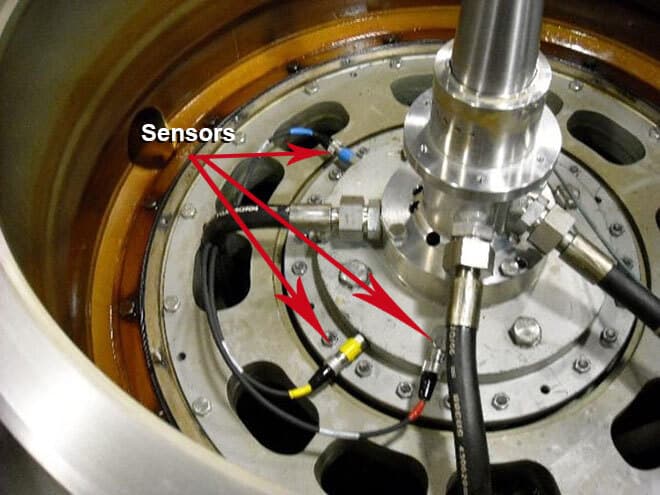

Allied Reliability’s solution included sensors mounted on the bearing housing, itself, using two radial sensors and one axial sensor (as shown in the photo below). This configuration was used instead of one tri-axial in case a sensor or cable goes bad (as is often the case), so the technician can continue to collect vibration data until the next scheduled preventive maintenance (PM).

The sensors were mounted on the housing, with the cables tied to the hose and then run down below the housing. The cables were run to the side, out the bottom of the access panel, to a box mounted on the outside of the housing (as shown in the series of photos below).

Allied worked closely with this customer following the new system installation. The following photos show the last defect that was found on a spindle bearing. We tracked the bearing defect for about 4 months between the first sign to the point where technicians were able to take the unit down to make the repair without affecting their production schedule.

Conclusion

This new setup with remotely controlled, internally placed sensors allows maintenance technicians to collect a better quality of vibration data on the spindle bearings. When the data was collected on the housing, it showed 1/10th of the vibration levels in the upper frequencies where early bearing defects first show up, compared to what is seen now with the new internal sensor setup. The cost of the parts for the system upgrade was minimal and easily made up for considering PM savings with easy access to data inside a machine that was previously inaccessible.

Contact an Allied Reliability representative to see how a similar solution might help obtain more accurate data on your currently inaccessible critical equipment.

ABOUT ALLIED RELIABILITY

Allied Reliability provides asset management consulting and predictive maintenance solutions across the lifecycle of your production assets to deliver required throughput at lowest operating cost while managing asset risk. We do this by partnering with our clients, applying our proven asset management methodology, and leveraging decades of practitioner experience across more verticals than any other provider. Our asset management solutions include Consulting & Training, Condition-based Maintenance, Industrial Staffing, Electrical Services, and Machine Reliability.

Subscribe to our Blog

Receive the latest insights on reliability, maintenance, and asset management best practices.