Reliability Improvement Roadmap Workshop

This workshop introduces the strategies required for asset reliability initiatives and provides insight into where your company can best benefit from focus and improvement.

Industries and organizations are going through a period of rapid technology changes that cause disruption along with innovation. Implementing new technologies to improve asset reliability, for example, is just the tip of the iceberg. Whether it is the adoption of condition-based maintenance for critical machinery or a similar shift in a manufacturing facility’s way of thinking and operating, what lies beneath ─ at the very foundation ─ is change management. This is critical to ensure the implementation is fully supported by the organization’s culture. It includes proper education/training in the new processes that employees will need to follow. It also requires governance for ongoing adherence to a different set of best practices. Depending on the size and significance of the change, it can call for the entire organization to adapt, from top to bottom.

Generally speaking, there are two main things that drive enterprise-wide changes: how complex is the change and how ready is the organization. Types of changes can be categorized as either programmatic or transformational:

Not all organizations have success when it comes to implementing new technologies. The successful ones are those who look beyond the technology, itself. Planning ahead of change is wise, and answering these questions is a good place to start:

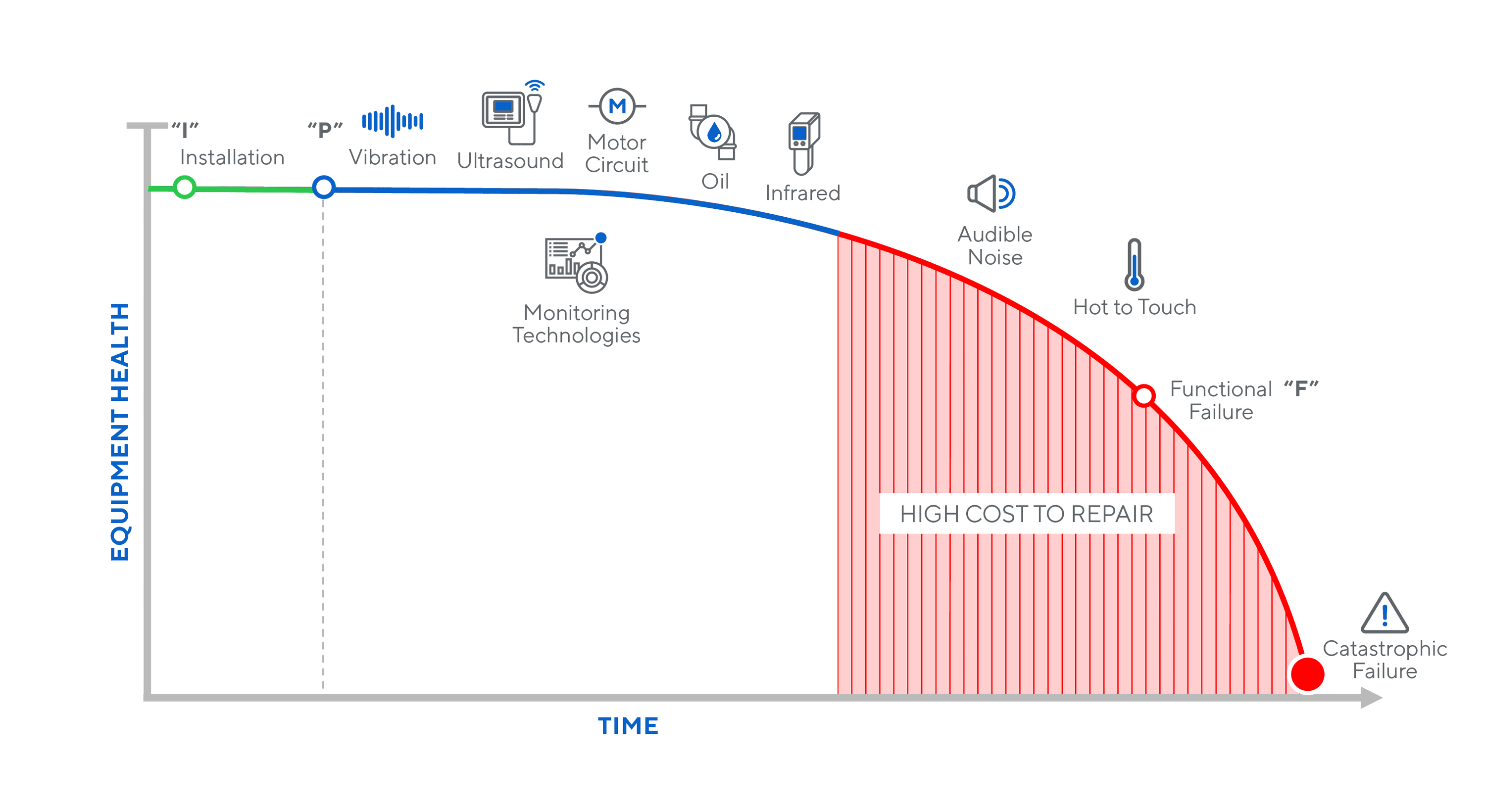

The P-F curve below has been modified to illustrate the importance of project governance and other organizational structures to avoid project failure.

Having the active involvement of your change management team, workstream champions, and leadership all contribute to structuring the change – leading to its ultimate success.

It is human nature to resist change. Most companies will need to confront the following seven organizational barriers:

Refer to our “Beyond the Technology” eBook for strategic solutions to these barriers. Download here.

We have found that strategic change management entails thinking through all of these elements, so that change sticks. The technology solution is not just something to be plugged right in; it requires time, attention, and finesse to roll out. In many cases, the technical change itself represents around 30%, while the organization and culture change can be as much as 70% of the overall effort. Allied Reliability can help at any stage of your technology implementation/change management journey to improve asset reliability, and increase the bottom line.

This workshop introduces the strategies required for asset reliability initiatives and provides insight into where your company can best benefit from focus and improvement.

Allied Reliability provides asset management consulting and predictive maintenance solutions across the lifecycle of your production assets to deliver required throughput at lowest operating cost while managing asset risk. We do this by partnering with our clients, applying our proven asset management methodology, and leveraging decades of practitioner experience across more verticals than any other provider. Our asset management solutions include Consulting & Training, Condition-based Maintenance, Industrial Staffing, Electrical Services, and Machine Reliability.

Receive the latest insights on reliability, maintenance, and asset management best practices.